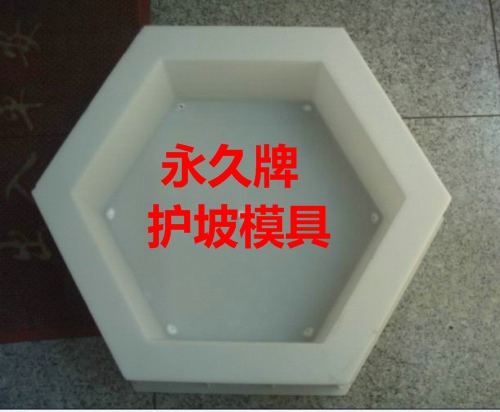

护坡模盒在应用生产方面,在模具内装入混凝土震动成型,自然凝固干燥后脱模具就可以使用了,模具表面光滑,不变形,不用托板,脱模时间短,可以定制设计。

In the aspect of application and production, the slope protection mold box is shaping by vibration with concrete in the mold. After natural solidification and drying, it can be used to remove the mold. The surface of the mold is smooth and does not deform. No bracket is needed, and the demoulding time is short, so the design can be customized.

塑料模具的成型方法有很多,例如压塑、挤塑、注塑、吹塑等,那么护坡模盒常用的生产方式有哪些呢。我们可以通过观察外观进行鉴别,可初步鉴别出护坡模盒所属大类

There are many moulding methods for plastic moulds, such as compression, extrusion, injection, blow moulding, etc. What are the common production methods of slope protection mouldboxes? We can identify the size of the slope protection box by observing its appearance.

无定形一般为无色,在不加添加剂时为全透明,硬度从硬于角质橡胶状,热固性护坡模盒通常含有填且不透料明。

Amorphous is generally colorless, transparent without additives, harder than keratinous rubber. Thermosetting slope protection box usually contains filling and is not clear.

注塑模具,主要是护坡模盒产品生产中应用最为普遍的一种成型模具,塑料注射成型模具对应的加工设备是塑料注射成型机,在注射机底加热料筒内受热熔融。

Injection moulds are the most widely used moulding moulds in the production of slope protection mouldboxes. The corresponding processing equipment of plastic injection moulds is plastic injection moulding machine, which is heated and melted in the bottom heating barrel of injection moulds.

然后在注射机的螺杆或柱塞推动下,浇注系统进入模具型腔,塑料冷却硬化成型,脱模得到制品。是护坡模盒制品生产中应用最广的一种加工方法。

Then, driven by the screw or plunger of the injection machine, the pouring system enters the mould cavity, the plastic is cooled and hardened, and the product is demoulded. It is the most widely used processing method in the production of slope protection box products.